ZIP System Vs. Tyvek HomeWrap

ZIP System Vs. Tyvek HomeWrap Pros And Cons

& Jorge Ibacache – Technical Services Engineer & Code Compliance Officer

Original Article Located at: CLICK HERE

On March 23, 2015, Jorge Ibacache and Patrick McPherson, two Quality Built Technical Services employees, wrote an article on the Zip Wall system entitled Just Zip It?. At the time, the ZIP System® was a relatively new product. Our two authors therefore focused their publication on the pros and cons of the system as they observed it. Over the course of the year, Quality Built has recognized a definite rise in builders adopting the ZIP System for their air and weather barrier installations. This rise seems to be linked directly to the claims that the ZIP System manufacturer, Huber Engineered Woods, LLC, is making regarding the speedy installation and extended warranty associated with the product. Many of our clients have asked us questions about the ZIP System and how it compares to its main competitor – the Tyvek® HomeWrap® system. In order to provide an un-biased detailed evaluation, we have analyzed the in-house data we have collected from our clients, as well as performed research through other credible sources to outline the pros and cons of both products.

Both the ZIP System and Tyvek HomeWrap system claim to be superior to one another. However, each system is different in nature. We will discuss these differences as we explain the pros and cons of each. One major thing that both of these systems have in common, are that they are both part of the building envelope and therefore have the potential to pose significant risk of water intrusion and damage if not properly installed and integrated.

ZIP System – Description

ZIP System is manufactured by Huber Engineered Woods, LLC. The ZIP System includes two main components; the Zip System® sheathing panels and the Zip System® tape. The panels are made up of OSB wood structural sheathing with an exterior facer of medium density phenolic-impregnated polymer-modified material. This facer qualifies as a Grade-D 60 minute WRB. The seam sealing tape is a polyolefin sheet with an acrylic adhesive backing that makes the tape self-adhesive. Huber describes the tape as being pressure-sensitive.Tyvek HomeWrap – Description

Tyvek HomeWrap is manufactured by E.I. DuPont De Nemours & Company, Inc. (DuPont™) DuPont Building Inovations. Tyvek HomeWrap is made up of olefin sheets that are manufactured from high-density polyethylene fibers. These sheets are non-woven and non-perforated and are manufactured by the material being flash spun-bonded using heat and pressure to create sheets of various sizes. The product is equivalent to a Grade-D 60 minute WRB.Pros Of The ZIP System

a. Quick Instillation As the Zip System panels have the WRB applied to the panels at the factory, there is a time saving in the installation – assuming the design calls for fully sheathed exterior walls and has no complicated elevation elements. This system becomes less time advantageous when the design includes complicated elevation elements that will require cutting panels of the sheathing to fit while maintaining the required 1/8 inch gap. The installation actually could be more time consuming and costly if the structural design does not call for fully sheathed exterior walls. Note that the sheathing must also be installed on all gable ends, etc. for a complete application – a task that would be accomplished more quickly and easily with a house wrap. b. Not As Susceptible to Wind Damage While Waiting for Cladding As the Zip System panels have the WRB applied to the panels at the factory, there is a time saving in the installation – assuming the design calls for fully sheathed exterior walls and has no complicated elevation elements. This system becomes less time advantageous when the design includes complicated elevation elements that will require cutting panels of the sheathing to fit while maintaining the required 1/8 inch gap. The installation actually could be more time consuming and costly if the structural design does not call for fully sheathed exterior walls. Note that the sheathing must also be installed on all gable ends, etc. for a complete application – a task that would be accomplished more quickly and easily with a house wrap. c. Thirty Year Warranty ZIP System offers a 30 year warranty, which is three times longer than the 10 year warranty offered by Tyvek®. However, there are a number of terms that purchasers should be made aware of, which we will discuss later in the cons section below.Pros Of Tyvek HomeWrap

a. Can be Applied Over Open Studs Since Tyvek HomeWrap is a sheet good, similar to traditional building papers, it can be installed over open stud framing as well as over sheathing. In some parts of the country it is standard to sheath the entire exterior. However, in many areas, that is not standard practice and Tyvek’s installation method may save material cost in those areas. b. Seams are Lapped, Not Butted Tyvek is a sheet good that comes on rolls and installs similar to traditional 60 minute building paper, which overlaps at the seams. While taping can be an issue (as we will discuss below in the cons section of installation), it does have an overlap to help protect the structure from water intrusion. c. Window Heads and Other Similar Conditions are Lapped in a Weatherboard Manner This was not the case when the product was newly on the market, at which time the instructions and details called for the Tyvek to wrap into the window opening and then the window was installed and taped on all sides to seal it. Several years ago Tyvek revised their installation instructions and details to provide a weather board lap at window heads and similar conditions.Cons Of The ZIP System

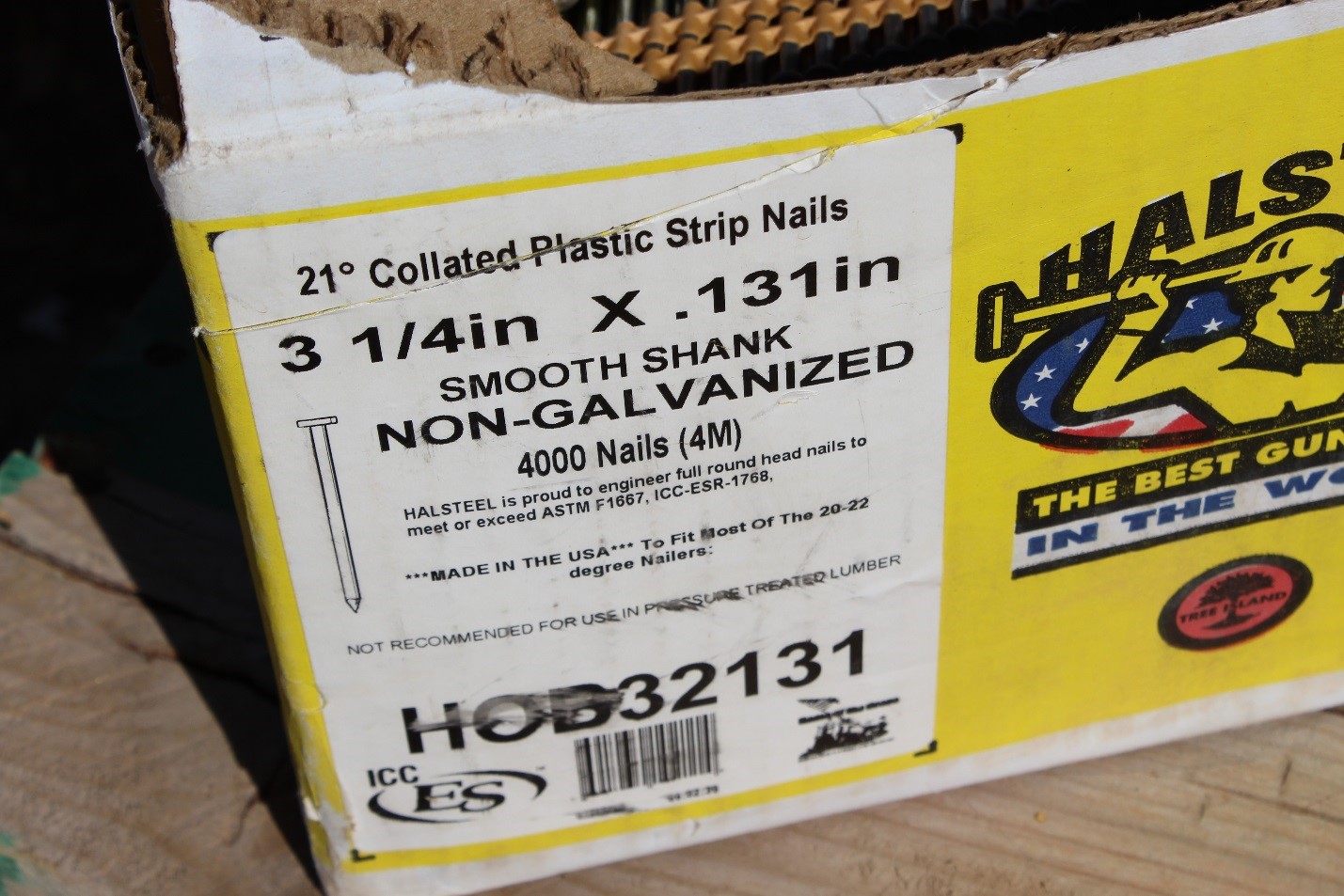

a. Sheathing Panels are Butted and Taped Creating a Reverse Lap The sheathing boards are butted together with a 1/8 inch gap between panels. This joint is then covered with the seam tape. This can create a path for water entry into the structure through wrinkles or improperly applied tape. The tape is required to be applied to clean, dry surfaces that are free of dirt, dust and frost. Contact of the adhesive surface of the tape with any foreign matter that may affect the bond must also be avoided. Both the air temperature, as well as the temperature of the sheathing must be at or above 20°F at the time of tape installation. Per the ICC ESR report, wrinkles in the tape are permissible “unless they create a leak path.” Unfortunately, we have seen the tape installed improperly on many occasions in the field. Improper installations have involved wrinkles allowing room for water leakage, as well as inadequate bonding due to the surface being dusty, wet or frosty. All of these issues will void the warranty. b. All Penetrations Create a Reverse Lap The method for treating any penetration including windows is to flash them with the ZIP System tape. This installation method results in a reverse lap at the head of penetrating items as indicated in the details provided in the ICC ESR report and on the Huber web site. These reverse laps are subject to the same issues discussed in the item above. c. Fasteners Can be Over-Driven, Damaging the Membrane Huber indicates that over-driven fasteners pose no problem other than possible structural loads for the panel. However, DuPont proved that water intrusion can occur at over-driven fasteners by performing water tests on this particular circumstance. d. The Entire Structure Must Be Sheathed Because the WRB is applied to the sheathing at the factory and is not available in sheet format like HomeWrap, the product cannot be installed over open stud framing like the sheet goods are capable of. Installation over open studs will require the installation of the sheathing with all required fasteners and seam sealing. This may increase cost for the material and install, which would contradict the time saving advantage that there claims to be. e. Framing Hardware is Not Behind the Weather Resistive Barrier (WRB) Since the ZIP System panels are already manufactured with the WRB attached, the framing hardware, such as straps, will occasionally be installed over the WRB. As water or moisture can accumulate and run down the WRB, the hardware is essentially exposed and the engineers and framers should pay special attention when selecting framing hardware and fasteners. These structural components will corrode at a higher rate than when installed behind the weather resistive barrier. f. Warranty is Non-Transferable Note that the ZIP System warranty is not transferable, and is only for the original home owner, builder, or commercial property owner. Warranty conditions and exclusions mean very difficult to get coverage. g. No Warranty Available for Some Condominium Projects Based on the language in the warranty indicating the types of products each applies to, many condominium projects may not be covered by a warranty at all. Any building where the units do not meet the single-family detached, duplex, or townhouse descriptions in the code, and that are not maintained in the possession of the original commercial owner will have no warranty coverage available. h. Need Galvanized Seismic Straps and Fasteners The warranty may be voided if it can be shown that the structure does not conform in any way to all applicable building codes and industry standards. Also, the warranty excludes conditions related to or caused by damage to the deterioration of the exterior wall or roof. A defense attorney for Huber could argue that this means damage caused to or by the ZIP System voids the warranty.Cons Of Tyvek HomeWrap

a. Can Be Damaged by Wind As the exterior cladding and thus the final fasteners and securement of the Tyvek HomeWrap may not be installed for several weeks after the HomeWrap, the HomeWrap is potentially subject to damage from high winds during this time. We have noted that the areas of the country where the risk of wind damage is the greatest are the same regions where the HomeWrap is being left exposed for longer durations with only the temporary fasteners installed to secure it in place. Additionally, a rep for the manufacturer in one of these areas is encouraging installers to use as few fasteners as they can so as to reduce the number of penetrations of the HomeWrap. While this makes sense from a water intrusion risk reduction stand point, the potential damage when the HomeWrap is blown off of the structure exposing the structure to potentially larger volumes of water is much greater. Additionally, as work progresses on the interior of the structure after the HomeWrap is installed and prior to the cladding being installed, the potential for other building products to be damaged increases. b. Is a Second Step Beyond Sheathing For areas of the structure that will receive sheathing on the exterior walls, the installation of HomeWrap is a second step that must occur after the sheathing is installed and in some cases inspected by the local jurisdiction for compliance with the braced wall plans and schedules. c. When Used as an Air Barrier, May Also Have a Reverse Lap The ZIP System is not the only system to incorporate a reverse lap. Many house wraps that will function as both a weather resistive barrier as well as an air barrier, incorporate a reverse lap. This occurs when the horizontal seams are taped to seal them to reduce the air leakage. See our tech alert on seam seal tapes for more information on this issue. One important distinction between the ZIP System and Tyvek, is that Tyvek HomeWrap is required to have six inches of overlap of the upper layer over the lower in a weather board fashion. While this does not prevent water that gets past a bad tape joint from getting into the structure, it does reduce the level of risk associated.Conclusion

We would recommend that you consult with building envelope experts as well as your insurance provider and have the warranties reviewed by a lawyer before deciding on which products to install – especially for high risk items like the WRB. Once you have decided on the product, we would recommend retaining an independent third party for Quality Assurance services to look at your plans and processes including; installation and testing, as well as documentation and correction of anomalies. You should also have a third party firm perform Forensic Quality Control testing to verify that the installation is providing the intended results. We have seen certified products which appeared to be properly installed, fail quality control tests. It is one thing for a product to pass laboratory testing and an entirely different thing to have it pass in the field when installed under field conditions. For more on this, see our tech alert on Forensic Testing. Reference Links Debris provides evidence of water migration behind seam seal tape. Note that the debris has spread horizontally along the seam: ZIP System tape was not adhered near the end of a seam at an inside corner:

ZIP System tape was not adhered near the end of a seam at an inside corner:

Typical of construction in a wet climate, the house wrap has mud and other debris on it. Similar conditions can be found with sheathing products. For wither product, this mud and debris must be cleaned off for the tape to bond to the WRB. It is not uncommon to find the tape not properly bonded because the surface is contaminated at the time the tape is being applied:

Typical of construction in a wet climate, the house wrap has mud and other debris on it. Similar conditions can be found with sheathing products. For wither product, this mud and debris must be cleaned off for the tape to bond to the WRB. It is not uncommon to find the tape not properly bonded because the surface is contaminated at the time the tape is being applied:

ABOUT THE AUTHORS

ABOUT THE AUTHORS

Jeff Hoch is a licensed architect and has been involved in the construction industry for over 27 years. He has a passion for safety and strives to educate the industry about building best practices and risk mitigation techniques. Jeff is constantly taking part in educational seminars and is extremely knowledgeable when it comes to building code requirements. Jeff performs inspections all across the nation and specializes in forensic inspections, AAMA/ASTM water testing, technical peer plan reviews, quality assurance, and much more. He also is extremely experienced with design standards, local ordinances, forensic building failure analysis, and construction defects.

Jeff Hoch is a licensed architect and has been involved in the construction industry for over 27 years. He has a passion for safety and strives to educate the industry about building best practices and risk mitigation techniques. Jeff is constantly taking part in educational seminars and is extremely knowledgeable when it comes to building code requirements. Jeff performs inspections all across the nation and specializes in forensic inspections, AAMA/ASTM water testing, technical peer plan reviews, quality assurance, and much more. He also is extremely experienced with design standards, local ordinances, forensic building failure analysis, and construction defects.